Methods for Efficiently and Elegantly Generating a Bill of Materials from the DEACOM Product Configurator

It’s often necessary to generate a fully-configured bill of materials (BOM), based on the customized product options that are chosen in a Product Configurator. One reason for this might be to develop the final cost of the product based on its sales order configuration in order to determine standard profit and margin calculations. Another reason might be a need for inventory relief. This can be done by either passing the full BOM to Production where materials can be issued and relieved by the production job, or by backflushing the BOM when the finished good is shipped without going through a production process. No matter the purpose, when fully-configured BOMs are needed, they can be developed by attaching item masters to the configuration options and then defining the BOM for those items.

DEACOM Product Configurator acts as a bridge between sales, production, and engineering departments for both manufacturers and distributors. As a native component to the main ERP system, customers can easily manage configuration workflows and BOM creation using the most accurate data and a single interface.

Throughout this article, we will be referring to “features” and “endpoints” within the configuration process. We define a feature as a group of similar, and usually mutually exclusive, endpoints (or options). A house, for example, might have a single space for a refrigerator, and the buyer could choose to have a 16 cubic foot, 18 cubic foot, or 20 cubic foot refrigerator in the space. In this scenario, the refrigerator is a feature, while the three size choices are endpoints.

Attachment of Item Masters to the Configuration

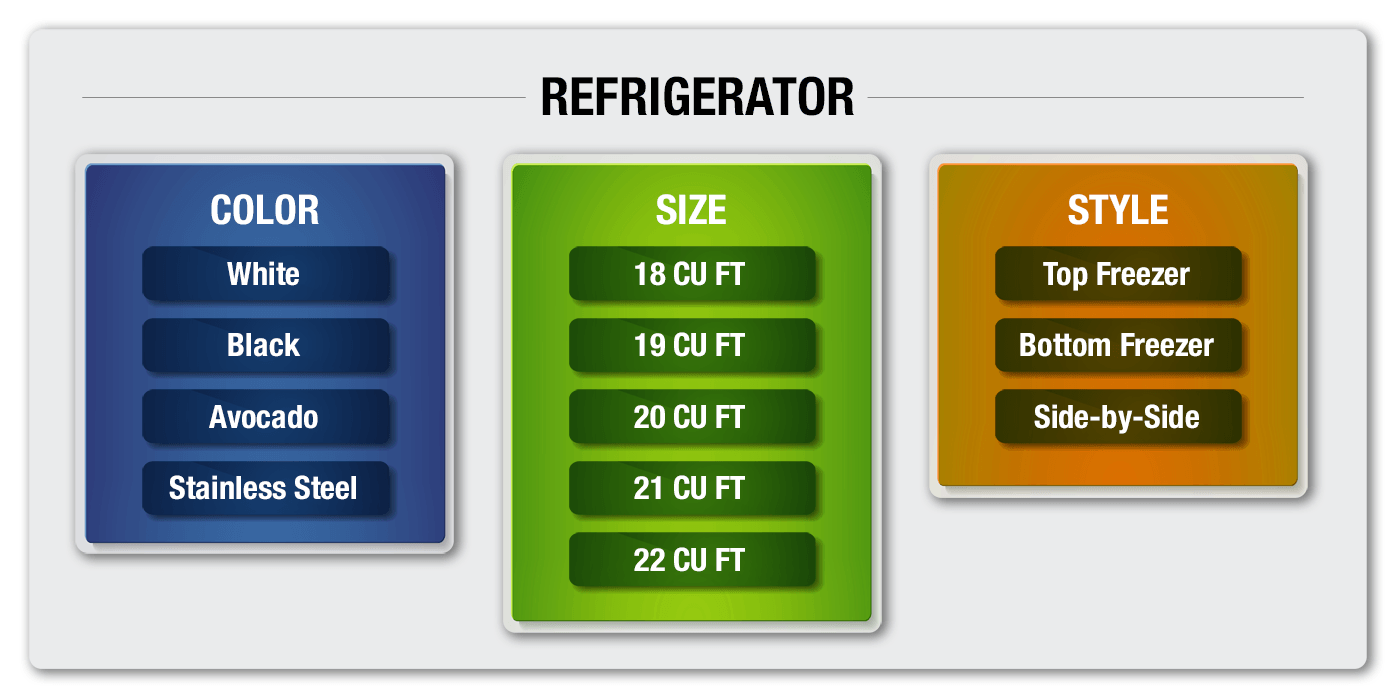

Consider the example of the refrigerator selection, which might come in four different colors (White, Black, Avocado, and Stainless Steel), five different sizes (18, 19, 20, 21, and 22 cubic feet), and three different styles (Top Freezer, Bottom Freezer, and Side-by-Side). There are a total of 60 possible combinations of those three characteristics.

On the item master side, there’s no choice but to have 60 different item masters, representing all those possible combinations. When it comes to the configuration side, DEACOM Product Configurator makes it possible to attach item masters to the configuration using two different methods:

- Directly attached to a product feature – This is the less desirable choice as it requires users to list all 60 endpoints under a single feature of “Refrigerator”, each one defined by color, size, and style. This very lengthy list makes it difficult to find and select the desired configuration during sales order entry.

- Attached to endpoints – The advantage of attaching item masters to endpoints, instead of attaching them directly to a feature, results in a very clean and intuitive configuration interface. This displays the three different features of “Color”, “Size”, and “Style” under a master feature of “Refrigerator”, each with their respective choices. If some of the combinations aren’t available, they can be controlled with inclusion/exclusion rules, rather than just having missing items out of the lengthy 60 option list.

Creation of Fully-Configured BOMs

If items included in the product configuration have their own BOM, then that is added to the BOM of the base item master creating a single BOM of the fully-configured item on the sales order.

Many times, the selection of a specific endpoint will unlock more options than just the ones selected. For example, the selection of a refrigerator with an ice maker might include plumbing components for water supply which may not be needed in other options. In this case, the item master that needs to be connected to the configurator endpoints is not the refrigerator itself, but a different item master with a bill of materials which includes both the refrigerator and plumbing components.

There are two main concepts for developing BOMs with options selected within the configurator, one that works well and another that doesn’t work as well.

1. Empty Base Item Master BOM – The first concept that works the best is where the base item master has a BOM that doesn’t include any of the components that might be added by configuration choices. As endpoints are selected, their respective BOMs are added to the base item master BOM. This is the most straightforward method for producing the complete bill of materials for the configured item.

In our example, there are 60 different available refrigerators, with varying combinations of characteristics: size, color, and style. Using this method of developing the BOM, those refrigerators would be represented by 60 item masters. The choice of the Avocado, 18 cubic foot, Top Freezer refrigerator is represented by a single item master. Simple!

2. Standard Configuration Starting point – The second concept that doesn’t work as well, but is still plausible, is one where the base item BOM contains all of the components associated with a standard configuration assuming all default choices are selected. Then, as options are selected in the product configurator, the item masters of the default endpoints are subtracted from the BOM and the new endpoints are added to produce the complete BOM of the configured item.

The problem with this concept is the exaggerated number of items and BOMs that are needed to make this work and the maintenance it requires. For example, if each of the 60 endpoints was a default choice in one configuration or another, there would need to be 3600 item masters and BOMs to handle all the variability! The reason for this is that it has to account for all possibilities of a default choice being removed and replaced by the endpoint selection. It has to have 60 different item masters, one that removes the White 18 cubic foot Top Freezer and replaces it with the Avocado 18 cubic foot Top Freezer, a second that removes the Black 18 cubic foot Top Freezer and replaces it with the Avocado 18 cubic foot Top Freezer, a third that removes the Stainless Steel 18 cubic foot Top Freezer and replaces it with the Avocado 18 cubic foot Top Freezer, and so on and so on. This causes a lot more, unnecessary maintenance in the backend!

Our first, preferred method requires much less setup and maintenance, where all product configurator choices are added to the base bill of materials. It’s a rather straightforward solution to what otherwise can be a complex problem – something we’re always striving for.