Food manufacturers need to leverage technology that can inform, track, and trace every ingredient to ensure safety and prevent recalls.

Undeclared food allergens are the leading cause of Class I food recalls, a situation in which the “use of or exposure to a violative product will cause serious adverse health consequences or death.” Considering that nearly 3% of Americans are allergic to peanuts (approximately 1 in 50 children and 1 in 200 adults), and other allergens are on the rise, the FDA released draft guidance on the matter.

With the health of consumers at risk and brand reputation at stake, and with millions of dollars potentially lost in the aftermath, food manufacturers cannot afford to let cross-contamination – and an inevitable recall – occur. They need to do their part to make sure that every item is labeled accurately and separate allergenic ingredients and allergen-containing food from all other packaged goods. And in order to do that, manufacturers need technology that can inform, track and trace every ingredient.

Ensure quality is maintained from conception to shipment

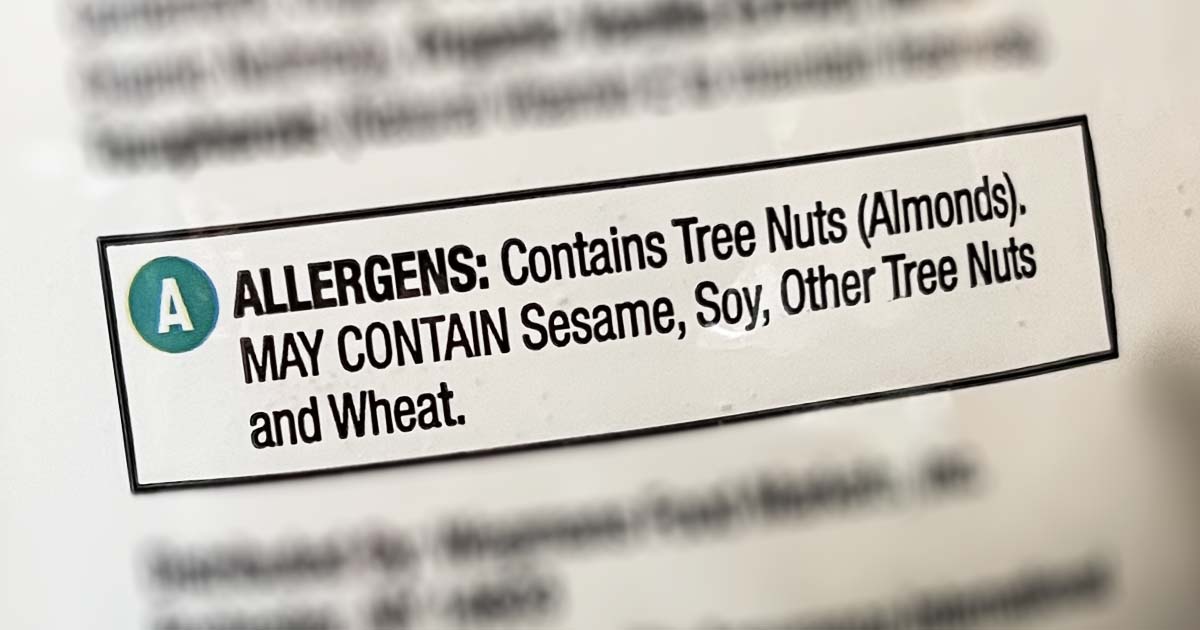

Quality control is essential, especially when dealing with allergens. Instead of simply stating that a product “may contain traces of nuts” or was “manufactured in a facility that processes nuts,” food manufacturers would be better off separating allergen-free products from the rest. This is not an easy task – milk powder, peanut dust and other allergens can spread quickly and are difficult to completely eliminate once they are introduced in a product line. If the proper cautions are not taken, all other product lines could be contaminated. This could lead to an undeclared allergen, or simply push manufacturers to add another blanket warning about a possible allergen. In both instances, affected consumers are prevented from safely consuming the product.

To prevent either scenario, manufacturers need powerful ERP technology that provides quality control checkpoints throughout production and generate the proper declared allergens on labels and documents. This enables manufacturers to quickly catch and rectify any issues before they escalate. They can also benefit by comparing quality control measures with actual quality control results. To further decrease the risk of a recall, manufacturers should constantly analyze and improve product data in real time and reduce prep time for audits by providing audit reports based on operational production data. If a recall is necessary, manufacturers can move faster and more efficiently to get the product off the shelves with technology that provides strict lot control with tracking and tracing functionality.

Empower brands and consumers with the right information

If an ingredient is skipped (ex: failing to list a soy-containing additive) on a label or mislabeled (ex: listing “oat flour” instead of “wheat flour”), consumer trust may be lost, and a recall may follow. Nutritional facts, like the amount of sugar or sodium per serving, are also vital to consumers as they consider what to eat.

Mistakes are more likely to occur when this information is entered manually or is stored in a separate system. With an automated solution, manufacturers can automatically add customer-defined information and completely eliminate the manual creation of allergy reporting and other requirements. In addition to what’s on the label, they should also use technology to manually generate Certificate of Analysis (COA) documents, which verifies that the product is in line with the brand’s requirements.

The critical aspect here is to offer clarity at all levels, providing brands with the confidence they need before going to market while allowing consumers to stay informed when making a purchase. This can be a life or death decision for consumers with allergies, but it goes beyond that. Everyone deserves to know what’s in their food, whether allergic to a particular ingredient or not. Some people may choose to avoid artificial colors, which have been known to cause allergic reactions, or monosodium glutamate (more commonly known as MSG), which can also cause a number of reactions. If these items are not clearly labeled, consumers will not be informed and therefore cannot avoid them – and if they get sick, they will have a difficult time determining why. By using the right technology to improve label accuracy, brands can avoid the fallout and ensure that consumers are able to make educated decisions about what they eat.

Don’t wait to deploy the necessary technology

Consumer safety is everything to food manufacturers, especially in environments where select ingredients could pose a health risk from exposure alone. But allergens are just the tip of the iceberg. Kraft Heinz recently recalled nearly 6,000 cases of Capri Sun Wild Cherry Flavored Juice Drink after a diluted cleaning solution (used on food processing equipment) was accidentally introduced into a production line.

In addition to the health risks (cleaning solutions are not safe for human consumption), the issue was only discovered after the company received complaints about the taste of the affected product. While no manufacturing method is foolproof, manufacturers must take the necessary precautions – and deploy the right technology – to stay informed about what goes on in their factories and what goes out as a finished product. By making smart choices now, manufacturers can be better prepared for tomorrow.

This article was originally published on IndustryToday.com.