It only takes one mistake – one distraction, contaminant, or error – to make a dramatic impact on your business. You never want to be the subject of a recall headline, turn away business because production had to be unexpectedly shut down, or threaten the health of consumers. But the fact is, that one mistake …

Maximizing Efficiencies in Chemical Manufacturing: An Overview of the Benefits of an ERP System

The chemical manufacturing industry is constantly evolving, and businesses need to stay ahead of the technology curve to remain competitive.Relying on manual processes hold you back, leading to inefficiencies and inconsistencies across your company, including financial reporting, warehouse management, quality control, and regulatory reporting. These issues hinder growth and put businesses at risk of non-compliance …

The Negative Impacts That Manual Processes Have on Your Business

Technology runs today’s world. Whether looking for a recipe or coding an AI robot, technology has made advancements in every aspect of our lives, and your business shouldn’t be left behind. Manual processes have become outdated in manufacturing and may hurt your business more than help. Challenges of Human Error and Inefficiencies of Manual Processes …

Continue reading “The Negative Impacts That Manual Processes Have on Your Business”

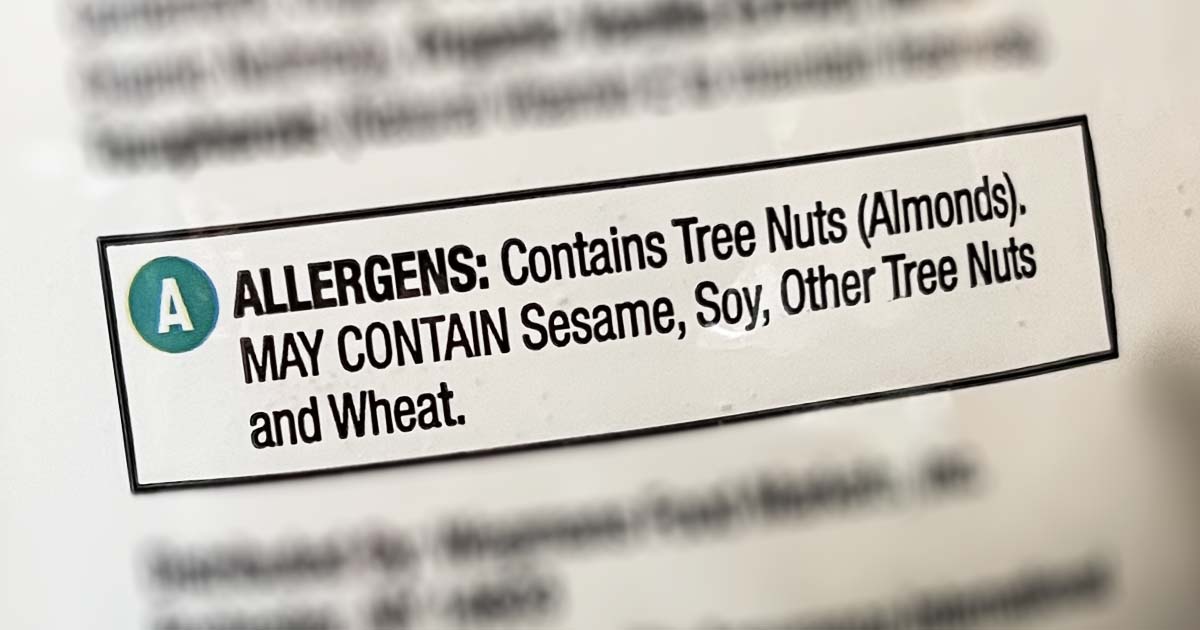

Preventing Mislabeled Allergens from Causing Harm

Food manufacturers need to leverage technology that can inform, track, and trace every ingredient to ensure safety and prevent recalls. Undeclared food allergens are the leading cause of Class I food recalls, a situation in which the “use of or exposure to a violative product will cause serious adverse health consequences or death.” Considering that …

Continue reading “Preventing Mislabeled Allergens from Causing Harm”

Why Shelf Life Rules Matter for Food Manufacturers

Every manufacturer has a responsibility to make their products as safe as possible for the end user. For those operating in the food and beverage sector, as well as reducing the risk of contamination and ensuring everything is prepared in a clean environment, clear adherence to – and labeling of – shelf life dates can …

Continue reading “Why Shelf Life Rules Matter for Food Manufacturers”

Hyper-Tight Process Control™ with the Deacom Warehouse Management System

One mistake — one distraction, one contamination, or one miscalculation – may have a significant impact in your organization. You never want to be the topic of a recall headline, lose money because manufacturing was abruptly stopped, or endanger consumers’ health. However, one error could ruin your reputation, sales, and, eventually, your bottom line. In …

Continue reading “Hyper-Tight Process Control™ with the Deacom Warehouse Management System”

How to reduce the “cost of being wrong”

The “cost of being wrong” can range from a few thousand to billions of dollars, not to mention the tarnished reputation, unless you have successfully implemented Hyper-Tight Process Control. Find out how it can protect your business.